APEX has attained the certifications of ISO9001 Quality Management System, ISO14001 Environment Management System, ISO45001 Occupational Health and Safety Management Systems, and operates and manages them in strict accordance with the system requirements.

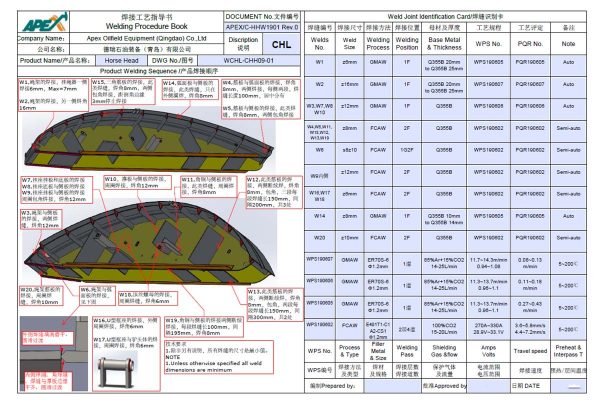

APEX has passed API Q1 Specification for Quality Management System Requirements for Manufacturing Organization for the Petroleum and Natural Gas Industry, and ISO 3834 and EN 1090 International Welding System Certification. At the same time, the products developed and produced by APEX have obtained API-11E, API-7K, API-8C, API-7-1, and other product certifications.

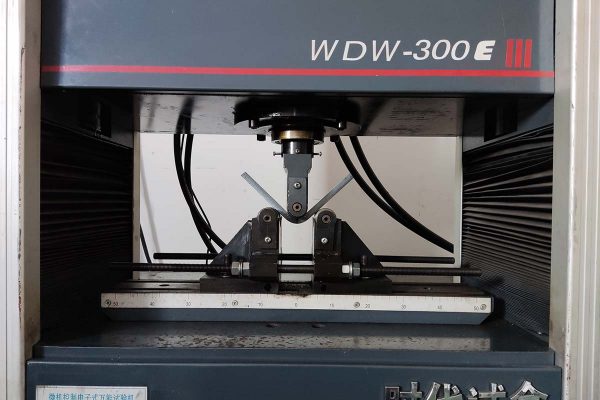

The process of product realization in each project is strictly controlled in accordance with the requirements of the quality system. All quality management staff for special processes are trained and certified.